3D printing has revolutionised industries and empowered hobbyists with the ability to create virtually anything. However, the type of filament you use significantly impacts the quality, durability, and functionality of your prints. In this guide, we’ll explore the most popular 3D printer filament brands, their applications, cost and where to find them.

PLA (Polylactic Acid)

PLA is the go-to filament for beginners and casual users because it’s easy to print, environmentally friendly and works well for decorative objects, prototypes, and non-functional models. Common applications include:

Uses

- Prototyping: PLA allows quick iteration of designs

- Educational projects: Safe and easy for students to use

- Home decor: Great for creating vases, ornaments, and sculptures (for inside use)

Pros

- Low warping

- Biodegradable (made primarily from corn starch and sugarcane)

- Vibrant and varied colour options

Cons

- Brittle compared to other filaments

- Limited heat resistance

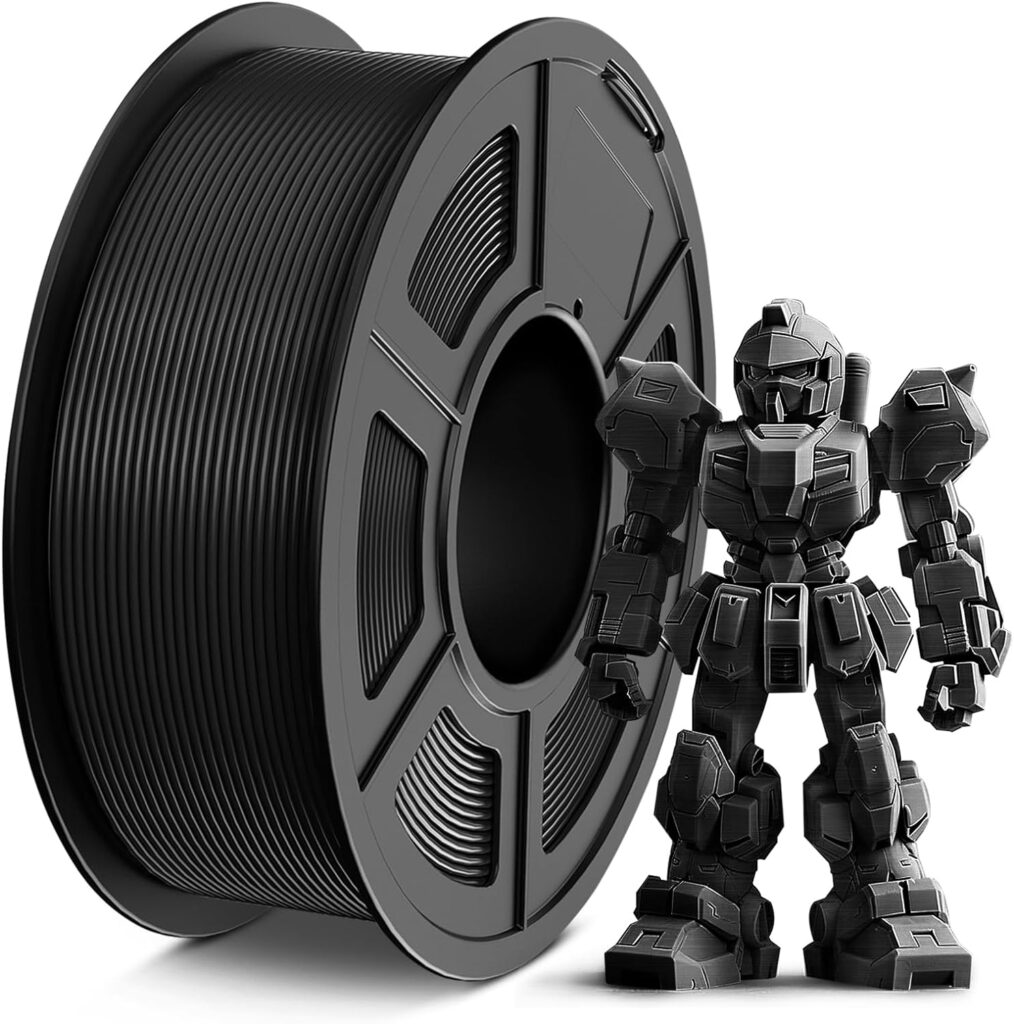

Want to try?

Here are two cost-effective options from leading brands.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and durable material commonly used for functional parts and tools.

Uses

It’s ideal for:

- Mechanical components: Gears, brackets, and housings

- Automotive parts: Durable and resistant to wear

- Wearables: Lightweight and durable designs

Pros

- High strength and durability

- Heat resistance

- Suitable for post-processing (sanding and painting)

Cons

- Emits strong fumes (requires proper ventilation)

- Prone to warping without a heated bed

Want to try?

Here are two cost-effective options from leading brands.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the ease of printing of PLA with the durability of ABS

Uses

It’s a great choice for:

- Food-grade items: Safe for cups, containers, and utensils (check certifications).

- Outdoor projects: UV and water resistance make it suitable for garden tools and outdoor signs.

- Transparent objects: Produces clear or translucent prints.

Pros

- Excellent durability

- Flexible yet strong

- Minimal warping

Cons

- Slightly more challenging to print than PLA

- Sensitive to over-extrusion

Want to try?

Here are two cost-effective options from leading brands.

TPU (Thermoplastic Polyurethane)

TPU is a flexible filament ideal for projects that require elasticity.

Uses

Applications include:

- Phone cases: Impact resistance and flexibility.

- Wearable gadgets: Comfortable and durable.

- Seals and gaskets: Ideal for waterproof designs.

Pros

- High flexibility

- Impact and abrasion-resistant

- Long-lasting elasticity

Cons

- Requires slower print speeds

- Challenging for beginners

Want to try?

Here are two cost-effective options from leading brands.

Nylon

Nylon is a strong, flexible, and abrasion-resistant filament perfect for heavy-duty applications.

Uses

Common uses include:

- Industrial components: Gears, hinges, and machine parts.

- Tools: Custom wrenches, screwdrivers, and jigs.

- High-stress applications: Handles, clips, and functional prototypes.

Pros

- High strength and durability

- Flexible and lightweight

- Resistant to chemicals

Cons

- Requires precise print settings

- Hygroscopic (absorbs moisture easily)

Want to try?

Here are two cost-effective options from leading brands.

Polycarbonate (PC)

Polycarbonate is an ultra-strong filament for professional-grade projects.

Uses

It excels in:

- Protective gear: Helmets and shields.

- High-temperature applications: Oven parts and fixtures.

- Transparent items: Clear lenses and covers.

Pros

- Extreme durability

- High heat resistance

- Impact-resistant

Cons

- Requires high print temperatures

- Prone to warping

Want to try?

Here are two cost-effective options from leading brands.

Carbon fibre reinforced filaments

Carbon fibre filaments used in 3D printing are typically made by infusing tiny carbon fiber strands into a base thermoplastic material (e.g. PLA, PETG). Carbon fibre filaments combine strength and lightweight properties.

Uses

Perfect for:

- Drone frames: Lightweight yet durable.

- Automotive components: Racing parts and brackets.

- Sporting goods: High-performance gear like bike parts.

Pros

- High strength-to-weight ratio

- Stiff and rigid

Cons

- Abrasive (requires a hardened nozzle)

- Expensive

Want to try?

Here are two cost-effective options from leading brands.

SUNLU Carbon Fiber PLA Filament

Choosing the right filament for your project

Selecting the right filament depends on your project’s requirements, budget, and printer capabilities. Ask yourself:

- Is strength a priority? Nylon or carbon fiber may be the best choice.

- Need something beginner-friendly? Start with PLA.

- Printing functional parts? ABS or PETG offers durability.

Caring for your filaments

No matter which filament you choose, proper storage is key. Most filaments are hygroscopic, meaning they absorb moisture from the air, leading to poor print quality. To maintain filament quality, store them in airtight containers with silica gel packets. For long-term storage, use filament dryers.

Leave a Reply