3D printing has democratised manufacturing, allowing individuals and businesses to create custom parts and prototypes. However, the cost of materials, particularly 3D printing filament, can quickly add up. Understanding how to calculate the filament cost per print is essential for budget-conscious creators who want to optimise their spending and maximise their return on investment. This guide provides a practical approach to calculating 3D filament cost per print, empowering you to make informed decisions.

Understanding the variables: filament weight, spool price, and print settings

Calculating filament cost per print involves considering several variables.

- Filament Weight: The weight of the filament used in a print is the most critical factor. This is typically measured in grams (g). Most slicing software, such as Cura or PrusaSlicer, provides an estimated filament weight for each print.

- Spool Price: The price of the filament spool is another essential variable. This information is readily available from online retailers or manufacturers.

- Filament Density: Different filament types have varying densities, which can affect the weight of the filament used. However, for most PLA prints, the density is relatively consistent.

- Print Settings: Print settings, such as infill density, wall thickness, and support structures, can significantly impact filament usage. Higher infill densities and thicker walls require more filament.

The formula: calculating filament cost per print

The formula for calculating filament cost per print is relatively straightforward:

Filament Cost Per Print = (Filament Weight (g) / Spool Weight (g)) x Spool Price (£)

For example, if you use 50g of filament from a 1kg spool that costs £20, the calculation would be:

Filament Cost Per Print = (50g / 1000g) x £20 = £1

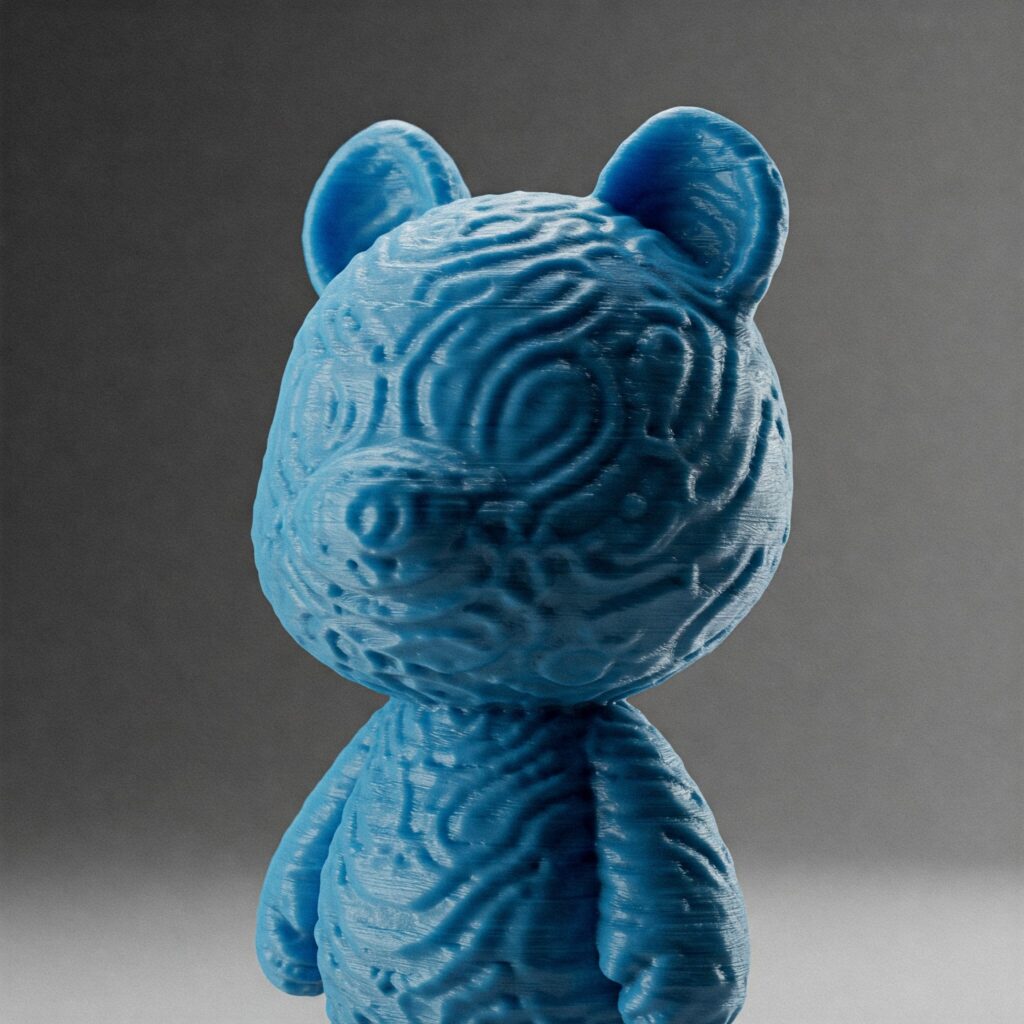

Cost per print can vary widely depending on spool price. For an example, let’s take a look at this guy:

If printed in entry-level PLA like the amazon basics one in blue below at £13 per 1kg spool, the cost per print would be £0.65.

However, if we go for a premium PLA like the Hatchbox periwinkle blue one below at £21 per 1kg, the cost per print would be £1.05.

Using slicing software for filament weight estimation

Slicing software plays a crucial role in estimating filament weight. Most slicing programs provide an estimated filament weight for each print, allowing you to calculate the cost before starting the print.

- Cura: Cura displays the estimated filament weight in the “Print Information” panel.

- PrusaSlicer: PrusaSlicer also provides an estimated filament weight in the “Print Statistics” panel.

- Simplify3D: Simplify3D offers a comprehensive “Print Information” panel that includes estimated filament weight.

Tips for minimising filament waste and reducing print costs

- Optimise print settings: Reduce infill density, wall thickness, and support structures to minimise filament usage.

- Use infill patterns: Choose infill patterns that provide structural integrity while minimising filament usage.

- Design efficient models: Design models that require minimal support structures and optimise for printability.

- Calibrate your printer: Properly calibrated printers produce fewer errors and reduce filament waste.

- Recycle failed prints: Failed prints can be recycled into new filament, reducing waste and saving money.

Beyond filament cost: considering other expenses

While filament cost is a significant factor, it’s essential to consider other expenses associated with 3D printing.

- Electricity costs: 3D printers consume electricity, which can add up over time.

- Maintenance costs: Regular maintenance and replacement of parts are necessary to keep your printer running smoothly.

- Post-processing costs: Post-processing techniques, such as sanding, painting, and finishing, can add to the overall cost.

By understanding the variables, choosing filaments cost-effectively, using slicing software, and implementing cost-saving strategies, you can effectively calculate 3D filament cost per print and optimise your spending.

Leave a Reply